what is NSK bearings and how it used?

Who is the best among the bearing Manufacturers?

Japan has solid competitiveness in the bearing industry.

The world’s top 10 bearing groups dominated the middle and high-end bearing industry.

The main consumption areas of bearings in the world are Europe, North America, and Asia. However, Asia has accounted for about 50% and is the most important consumption area, though Europe and North America account for 25% and 20% correspondingly.

NSK is the largest bearing provider, with a 2% market portion; in Central Europe, China, and Eastern Europe, limited bearings dominate.

The bearing industry has long remained a specific important component manufacturing segment.

Its accuracy is characteristically measured in microns, but the modest manufacturing difference for mechanical components is commonly only 0.01mm. Sounds and vibrations produced by the motor are mostly determined by the value and expertise of the bearing.

NSK extended its business rapidly in Asia in the mid-nineties.

To perform sales, research and development, and technical services locally.

Particularly in fast-developing markets such as China, NSK is constantly solidifying its corporate structure.

NSK bearing what is it how is it used types of nsk bearings?

Miniature bearings - are sometimes mentioned as tool bearings or micro bearings and are cast off in applications as vary.

Spherical roller bearings - spherical roller bearing designated in rolling-element bearing that allows rotation with low friction and permits angular misalignment.

Angular contact ball bearings - are designed specifically for both axial and radial loading, and are specifically engineered for use in top speed and high precision.

Cylindrical roller bearings - have a modest structure with their cylindrical rollers in line contact with the raceways. They can provide high load volume under radial loads. They are also designed specifically for both axial and radial loading.

Deep groove ball bearings - are the most generally used bearing type and are particularly multipurpose. They have low resistance and are built for small noise and little vibration which provides maximum rotational speeds.

Needle roller bearings/needle bearings - They are considered as thrust or radial bearings built on which load direction they are used. Long and narrow cylindrical rollers that occasionally exceed JIS/ISO scope ranges.

Tapered roller bearings - are exactly designed to manage together with axial and radial loads, even in the most demanding conditions.

Thin section ball bearings - facilitate the solid design of industrial audio-visual, medical, robots, and office automation equipment.

Thrust ball bearings - It has two variants, the single direction, and double direction. Single direction Thrust Ball Bearings are used in pressed steel cages and machined brass cages while the Double- Direction Thrust Ball Bearings are almost the same in a single direction there is a difference in diameter series.

How is an NSK bearing made and what are its components?

NSK bearing rings and rolling elements are subject to repetitive high pressure with a minimal amount of sliding.

The enclosures are subjected to tension, compression, and sliding contact with the rolling elements and whichever or both of the NSK bearing rings.

Therefore, the components used for the rolling elements, rings, and cages need the following characteristics:

-

High rolling contact fatigue strength

-

High hardness

-

High wear resistance

-

High dimensional stability

-

High mechanical strength

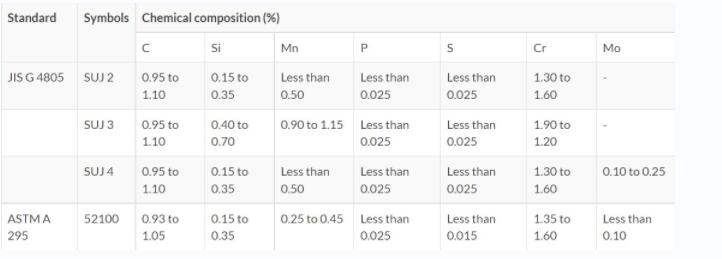

Here are the materials and composition for NSK bearing rings and rolling elements:

What types of NSK bearings are available on the market today and what are their features and benefits?

Deep Groove Ball Bearings

-NSK manufactures a full variety of deep-channel ball bearings. These bearings are the most common type and are used in different variety of applications.

Angular Contact Ball Bearings

-The NSK variety of angular contact ball bearings has been intended to meet the progressively demanding requirements of original equipment manufacturers.

These bearings have a contact angle so that they can endure significant axial masses in one way together with radial loads.

Features

-

High-Quality Steel

-

Advanced Grease Technology

-

High-Graded Balls

-

Super Finished Raceways

-

Contact Angle

-

Cages

Self-Aligning Ball Bearings

-This type of ball bearing is suggested when the alignment of the housing and shaft is problematic and the shaft may bend.

The external ring has a spherical channel and its center of curving coincides with that of the bearing; thus, the axis of the internal ring, balls, and cage can bounce to some amount around the bearing center.

Thrust Ball Bearings

-Thrust ball bearings are classified into those flat seats or aligning seats depending on the shape of the outer ring seat.

They can endure axial loads but not at all radial loads. In Single-Direction Thrust Ball Bearings, hard-pressed steel cages and machined brass cages have usually used the cages in Double- Direction Thrust Ball Bearings are the same as those in Single-Direction Thrust Ball Bearings of the same diameter sequence.

Features

Available in a single direction and double direction.

-

High-quality steel-ultra clean steel

-

Advanced Grease Technology

-

High-Grade Balls

-

Optional seating rings take initial misalignment

N Series Thin-Section Ball Bearings Metric and Inch Designs

-Extremely thin-section ball bearings and roller bearings contribute to trimming, weight saving, and lessening of torque loss of machines, construction equipment, and manufacturing machinery.

FEATURES

-Low frictional and irregular torque ensure extremely effective power transmission and even rotating performance.

-The high exactness of the bearings allows excellent high-speed performance.

How is it different from other types of bearings?

Most of us know that there are a lot of different kinds of bearings. There are bearings made for a typical car, tough environments, structural modifications, Plummer blocks, stable operation, washing machines, air conditioners, and bearing for high axial forces, low torque, and high speeds.

Ball Bearings

-

Ball bearings’ design makes them proficient in enduring axial loads.

-

No heavy loads, This can result in early destruction with huge loads.

Roller Bearings

-

Can take high radial loads

-

Mainly used to adjust the axial displacement

-

Has low vibrations

Spherical Roller Bearings

-

Usually used in applications where heavy loads are, modest to high speeds and possible misalignment arises.

-

Spherical roller bearings have spherical sides that fit the spherical raceways and handle tiny misalignments.

Tapered Roller Bearings

-

contains variations of a cone as the primary load-carrying element.

-

composed to carry higher axial loads and radial loads.

Needle Roller Bearings

-

is a special type of roller bearing that takes cylindrical rollers that look like needles because of their minor diameter.

-

have a lesser diameter, and more rollers can fit in the same space which rises the surface area in interaction with the races.

When to use which type of NSK bearing?

When to Use Roller Bearings?

-

Roller bearings are the common type of bearings. It is mainly used for Heavy loads and low-speed ability.

Plain Bearings

-

Plain bearings are used for sliding, reciprocating or oscillatory, and motion rotational. The bearing remains stable while the journal slides on the bearing’s internal surface.

Needle roller bearings

-

Needle roller bearings are good in machines, cars, light trucks, and two and three-wheelers.

Tapered roller bearings

-

This kind of bearing is perfect for radial forces and thrust loads. This bearing must be properly lubricated to maximize smooth and long life.

Here are also some other considerations about when and which type of NSK bearing is suitable for you:

Identify the Bearing Space/Bearing's bore size

Load Volume and Allowable Speed ability

Misalignment of the Inner ring and Outer ring

Firmness and Running Accuracy

Torque and Noise

Mounting and Dismounting of NSK Bearing Types

How to select the right NSK bearing for your needs?

The size of the NSK bearing is selected to satisfy the chosen life requirement. When doing this, in addition to fatigue life, it is essential to observe grease life, wear, noise and vibration, and other factors.

An example of NSK bearing choice procedures are:

1. Operating conditions and required performance

-

Environmental conditions

-

Dimensions of shaft and housing

2. Evaluation of NSK bearing types

-

Allowable space

-

Magnitude and direction of loads

-

Vibration and shock

-

Operating speed, maximum speed

-

Misalignment of inner and outer rings

-

Fixing in the axial direction and mounting arrangement

-

Ease of bearing mounting and dismounting

-

Sound and torque

-

Required rigidity

-

Availability and cost

3. Stability of bearing type and mounting fitness

-

The expected life of the machine

-

Dynamic and static equivalent loads

-

Speed

-

Permissible static load factor

-

Allowable axial loads (for NSK cylindrical roller bearings)

4. Selection of bearing accuracy class

-

Running accuracy

-

Rotational stability

-

Torque fluctuation

5. Examination of internal clearance

-

Fitting

-

The difference in temperature between the outer and inner rings

-

Speed

-

Misalignment of inner and outer rings

-

Amount of preload

6. Study of cage type and material

-

Speed and Noise

-

metric bearing series

-

Operating temperature

-

External vibration and shock

-

Rapid acceleration and deceleration

-

Moment load and misalignment

7. Selecting of lubricating method and type of seals

-

Operating temperature range

-

Speed

-

Lubricating methods

-

Type of seals

-

Maintenance and inspection intervals

8. Examination of ease of mounting/ dismounting

-

Procedure for mounting and dismounting

-

Necessary equipment

-

Dimensions affecting mounting

9. Specifications of NSK bearing and surrounding parts

Where can you buy NSK bearings online?

Planning to buy your NSK bearing? Look at the websites below for the list of various bearing manufacturers:

How do you properly maintain your NSK bearings to ensure optimal performance over time?

Maintenance and Inspection

To achieve the optimal potential of NSK ball bearing units, we provided the checklist for you:

-

Regular Inspection of Bearings

-

Schedule your Bearing Cleaning

Here are also some lists or significance that your bearings are needed for your attention:

a. When there are cracks in the outer or inner rings, cage, or any rolling elements.

b. When there is peeling of the channel or rolling elements.

c. When there is significant wiping of the ribs, raceway surfaces, or rolling elements.

d. When the cage is significantly damaged or rivets are slack.

e. When there is rust or marking on the rolling elements or raceway surfaces.

f. When there is any significant impression or hardness traces on the raceway surfaces or rolling elements.

g. When there is the sign of creep on the bore or the border of the outer ring.

h. When discoloration by heat is obvious.

i. When momentous damage to the seals or shields of grease-sealed bearings has happened.

-

Detecting and Correcting Irregularities

-If an irregularity is found during the inspection, the cause should be verified and the proper corrective actions should be done. If necessary, the bearing should be dismounted and inspected in detail.

Conclusion

The purpose of this research was to educate bearing users. Based on the analysis transported, it can be concluded that there are multiple and different kinds of bearings and functions. The research could improve the lives of others working in bearing industries