Four-row tapered roller bearings 101

Four-row tapered roller bearings are designed to provide high radial and axial loads, high speeds, and superior accuracy and durability.

These bearings are perfect for heavy-duty applications in the automotive, agricultural, and industrial markets.

Four-row tapered roller bearings are an essential component for many heavy-duty industrial applications.

Learn more about their design, features, and benefits in this comprehensive guide.

Four-row tapered roller bearings are designed to carry heavy radial and thrust loads in both directions.

They feature four rows of tapered rollers, arranged back-to-back, and two rows of cylindrical roller bearings. They are suitable for high radial and axial loads, as well as high speeds.

Four-row tapered roller bearings are designed to withstand heavy loads and are perfect for applications that require precise and precise operation. Continue reading to know more!

Introduction

A.Definition of Four-row tapered roller bearings

Four-row tapered roller bearings are a type of bearing used to support heavy radial and axial loads in applications such as rolling mills, machine tools, and conveyors.

They are composed of four rows of tapered rollers arranged in a triangular pattern, with two rows facing outward and two rows facing inward.

The inward-facing row is designed to provide axial stability, while the outward-facing rows are designed to support the radial load.

B.Benefits of using Four-row tapered roller bearings

1.Increased load capacity:

Four-row tapered roller bearings have a greater radial load capacity than other types of bearings due to the larger number of rolling elements.

2.High-speed capability:

The increased number of rolling elements makes four-row tapered roller bearings suitable for higher-speed applications.

3.Longer service life:

The four-row design ensures a longer service life compared to other types of bearings due to the increased number of rolling elements and the higher load capacity.

4.Reduced vibration and noise:

The four-row design reduces vibration and noise by distributing the load more evenly across the bearing.

5.Increased accuracy:

The four-row design ensures greater accuracy and better alignment of the bearing’s components.

6.Lower cost:

The larger number of rolling elements and the increased load capacity of four-row tapered roller bearings means that they are often less expensive than other types of bearings.

Types of Four-row tapered roller bearings

A.Single-row tapered roller bearings

Single-row tapered roller bearings are bearings with tapered rollers that are used to support combined loads, such as radial and axial loads.

These bearings have tapered inner and outer ring raceways that are offset from each other, allowing the rollers to roll in a linear motion.

Single-row tapered roller bearings are used in a variety of applications, including automotive, agricultural, and industrial applications.

B.Double-row tapered roller bearings

Double-row tapered roller bearings are roller bearings that have tapered raceways on both the inner and outer rings, allowing them to support axial and radial loads.

The tapered contact surfaces enable them to absorb higher loads than single-row versions, making them a popular choice for automotive, agricultural, and industrial applications.

C.Four-row tapered roller bearings

Four-row tapered roller bearings are a type of roller bearing used in heavy-duty machinery and industrial applications.

They are capable of supporting both radial and axial loads and are designed to handle higher loads than double-row tapered roller bearings.

Four-row tapered roller bearings are often used in applications such as machine tools, gearboxes, and conveyor systems.

Construction and Design of Four-row tapered roller bearings

A.Cages

The cages of four-row tapered roller bearings are designed to provide support for the rollers and to reduce friction between the rollers and the bearing rings.

There are several types of cages available for four-row tapered roller bearings. The most common cages are stamped steel cages, machined steel cages, and nylon cages.

Stamped steel cages are made from thin steel plates and are relatively inexpensive.

Machined steel cages are more durable and provide better load-bearing capabilities, but they are more expensive. Nylon cages are lightweight and offer excellent corrosion resistance, but they are not as strong as other cages.

B.Separators

The four-row design consists of two inner rows of rollers and two outer rows of rollers and separators.

The separators, which are made of strong synthetic material, are designed to keep the rollers in place, preventing them from shifting and allowing them to move freely.

The separators also help reduce friction and vibration, allowing the bearing to operate at higher speeds and with greater efficiency.

The separators also help to reduce the amount of heat generated during operation, prolonging the life of the bearing.

C.Rollers

Four-row tapered roller bearings are bearings that consist of four rows of tapered rollers and are used in heavy-duty types of machinery, such as rolling mills, compressors, and paper-making machines.

They are designed to carry large radial and thrust loads and are usually mounted in two or four pieces.

They are very efficient at handling loads in both directions and are also used in applications such as crane booms, mining equipment, and machine tools.

They are available in many sizes, with bore sizes ranging from 1 inch to 6 inches and a variety of cage styles to choose from.

Applications of Four-row tapered roller bearings

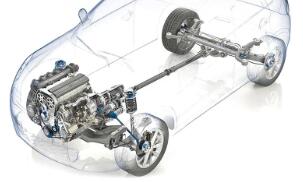

A.Automotive

Four-row tapered roller bearings are widely used in automotive applications due to their high-load capacity, low friction, and long service life.

They are most commonly used in steering columns, steering knuckles, transmission and axle shafts, differential carriers and hubs, and wheel hubs.

Four-row tapered roller bearings provide the strength needed to withstand the high radial and axial loads associated with automotive applications.

They also provide the ability to precisely control the amount of play between the bearing and the shaft, which helps reduce vibration and noise.

Additionally, they are less sensitive to misalignment than some other types of bearings, making them a cost-effective choice for automotive applications.

B.Heavy machinery

Four-row tapered roller bearings are used in heavy machinery applications where high load capacity and long life are required.

These bearings are designed to provide reliable, efficient operation in the toughest of conditions.

The four-row design provides greater radial load capacity, allowing for larger shaft diameters and higher speed capabilities.

Additionally, the tapered roller design helps to reduce friction, which increases bearing efficiency and life.

In applications where shock loads are present, such as in construction equipment, four-row tapered roller bearings are a great solution.

The design allows for greater shock absorption and load-carrying capacity than standard two or three-row bearings.

These bearings can also be used in applications where high speed, high precision, and low vibration are required, such as industrial machinery. Four-row tapered roller bearings are also used in agricultural types of machinery, such as combines, tractors, and harvesters.

The design helps to reduce vibration and wear, which increases the life of the machinery and reduces maintenance costs.

Additionally, the design helps to provide more efficient power transfer from the engine to the wheels, making the machinery more efficient and powerful.

C.Aerospace

Four-row tapered roller bearings are typically used in aerospace applications such as aircraft landing gear, where they can support heavy loads and withstand the high forces generated during take-off and landing.

They are also used in helicopter rotors and gyroscopes, providing high levels of accuracy and reliability.

Conclusion

Four-row tapered roller bearings are a great option for applications that require both radial and axial loads.

They can handle high loads, are durable, and are easy to install and maintain. In conclusion, four-row tapered roller bearings are a reliable and cost-effective choice for many applications.