A Comprehensive Guide to Installing Ball Bearings in 2023

This guide will provide step-by-step instructions on how to install ball bearings in 2023, with expert advice on the materials and tools needed.

Learn the best methods for achieving a professional, reliable installation.

Are you looking to install ball bearings in 2023? This comprehensive guide will provide you with the tools and knowledge to install ball bearings with ease and confidence.

You'll learn about the installation process, what tools you'll need, and the best practices for a successful installation.

Installing ball bearings in 2023 requires the use of a special tool to ensure proper installation.

The tool should be inserted into the bearing and used to ensure the bearing is properly seated and aligned.

Once the bearing is in place, tighten the bolts to secure the bearing place.

In 2023, the world of ball bearings changed dramatically.

This comprehensive guide will help you navigate the newest installation techniques and technologies, ensuring a successful and efficient installation process.

Types of ball Bearings

1.Single Row / Double Row Angular Contact Bearing

A single-row angular contact bearing is a type of bearing that is composed of two rows of balls and one inner and one outer raceway.

It is designed to support radial and axial loads in one direction.

The single-row angular contact bearing is capable of taking higher loads in one direction and is generally used in applications that require high speed and accuracy.

A double-row angular contact bearing is a type of bearing that is composed of two inner and two outer raceways.

It is designed to support radial and axial loads in both directions.

The double-row angular contact bearing is capable of taking higher loads in both directions and is generally used in applications that require higher speed and accuracy.

2.Four Points Angular Contact Bearing

Four Points Angular Contact Bearings are high-precision components used in a wide range of industrial applications.

They feature four contact points and a unique design, which enables them to support both radial and axial loads.

These bearings are known for their ability to withstand extreme temperatures, loads, and vibrations.

3.Single Row / Double Row Deep Groove Ball Bearing

Single-row deep groove ball bearings are the most widely used bearing type, offering a large load-carrying capacity in a relatively small space.

They are characterized by having deep raceway grooves in which the inner and outer rings have circular arcs of a slightly larger radius than that of the balls.

Double-row deep groove ball bearings provide the same load-carrying capacity as single-row bearings, but with increased radial stiffness and higher axial stiffness.

They are suitable for applications where the inner and outer rings are subject to axial and radial loads, such as in a four-point contact bearing.

4.Duplex Ball Bearing

A duplex ball bearing is a type of bearing that uses two sets of balls to support a load.

This type of bearing is usually found in high-load and high-speed applications, such as electric motors, turbines, and pumps.

The two sets of balls are arranged in a V-shape to create a deep groove in the bearing, allowing for greater load capacity and increased rotation speed.

Duplex ball bearings are typically made from high-grade steel, and are very durable, making them ideal for long-term use in demanding applications.

5.Miniature Bearings

Miniature bearings are small, lightweight bearings designed to fit in tight spaces and support small loads.

They are typically made of hardened steel, stainless steel, or brass and can be lubricated with oil or grease.

6.Precision Ball Bearings

Precision ball bearings are cylindrical roller bearings that are designed to offer high accuracy, low noise, and low friction.

They are frequently employed in high-precision fields like aerospace, medicine, and the military.

7.Self-Aligning Ball Bearings

Self-aligning ball bearings are a type of bearing used in industrial machinery, typically in applications where the alignment of the shaft and housing is not perfect.

These bearings feature two rows of balls which are held in place by two rings, one inside and one outside.

The outside ring is slightly larger than the inside ring, allowing the bearing to move and self-align when the shaft and housing are misaligned.

This provides a smoother, more efficient operation than fixed-alignment bearings, which can cause grinding and resistance if the alignment is off.

8.Single Direction/ Double Direction Thrust Ball Bearing

A Single Direction/ Double Direction Thrust Ball Bearing is a type of roller bearing that is designed to support axial loads in both a single direction and a double direction.

These bearings are composed of two races, which are separated by several ball bearings.

As the name suggests, the single-direction thrust bearing is designed to support loads in a single direction, while the double-direction thrust bearing is designed to support loads in both directions.

This type of bearing is ideal for applications requiring axial loads and is commonly used in automobile transmissions, machine tools, and other industrial machinery.

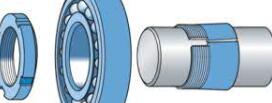

Component

2 rings/races,

Ball bearings are composed of two rings or races, which are made of hardened steel.

The inner race is mounted on the shaft and rotates with it, while the outer race is mounted in a housing and does not rotate.

The balls spin between the two races, providing smooth, low-friction motion and reducing the rotational torque required to move the load.

the balls (the rolling elements),

Ball bearings are small metal balls that are placed between two surfaces to reduce friction and enable smooth, efficient rotation.

They are used in a wide variety of machines, from cars and computers to watches and roller skates. Ball bearings reduce wear and tear on moving components and allow them to move smoothly and efficiently.

the retainer (the ball separator).

The ball bearings retainer, also known as the ball separator, is a device that keeps ball bearings in place and prevents them from becoming loose.

It is an important component in many mechanical systems, as it helps reduce friction and wear on the ball bearings, allowing them to last longer and perform better.

Preparing for Installation

Cleaning the installation surface

Before installing ball bearings, it's important to ensure the surface is clean.

Use compressed air to blow away dirt, dust, and other debris, then use a soft cloth and mild detergent to wipe away any remaining contaminants.

This will help ensure the ball bearings are properly seated and will last longer.

Ensuring the proper lubricant is used

It's important to use the correct lubricant for ball bearings to ensure optimal performance.

Check the manufacturer's guidelines for the type and amount of lubricant to use.

Different bearing materials and operating conditions may require different lubricants.

Too little or too much lubricant can cause decreased performance and damage to the bearings.

Making sure the tools needed for installation are available

It is important to make sure all the tools necessary for the installation of the ball bearings are available before starting the process.

This includes the appropriate wrenches, screwdrivers, drills, and any other necessary tools to ensure that the job is done properly and safely.

Having the right tools will make the installation process go smoother and will help avoid any unnecessary delays.

Installing a Ball Bearing

Mounting the bearing

Mounting the bearing requires precise alignment to ensure a proper seal. It involves placing the bearing into the housing and securing it with set screws or a locking collar.

Lubrication

When installing a ball bearing, it is important to apply the right amount of lubricant to ensure the bearing runs without friction.

This lubrication helps protect the bearing from wear and tear, which can reduce its life.

Test running of the equipment

This includes checking the rotation of the bearing, its noise, vibration, temperature, and lubrication to ensure that it is running correctly before use.

Possible issues that can arise from improper installation

Never place aluminum parts on hot plates of any kind.

Never place aluminum parts on hot plates as it can cause ball bearings to overheat and ignite, leading to a hazardous situation.

Before using, ensure sure all components are installed correctly because doing otherwise can result in serious harm and injury.

Don't use a torch if you want to keep the housing and other parts undamaged.

Don't use a torch to install ball bearings - the heat can cause damage to the housing and other parts.

It's important to use the right tools and techniques to ensure a proper installation that won't cause any damage. Seek professional help or advice if you're unsure.

Don't heat up the bearing. It expands and makes the removal almost impossible.

The expansion caused by heat can lead to the bearing being stuck in the housing and unable to be removed.

It is best to use the correct tools and techniques when installing and removing ball bearings to prevent any potential harm.

Don't cool off the bearing as you'll also shrink the cases.

As a result, the cases may shrink as a result of thermal expansion and contraction, which could harm the bearings and the case.

It is important to ensure that the bearings are properly lubricated and installed to prevent any damage.

Conclusion

Installing ball bearings in 2023 is a simple process that requires the right knowledge and tools.

With the right technique and equipment, you can ensure your ball bearings are installed properly and last for many years.