Easy and quick to know CARB toroidal roller bearings

This comprehensive guide will teach you everything you need to know about CARB toroidal roller bearings.

Discover the design, construction, advantages, and applications of these versatile and reliable bearings

Get a comprehensive understanding of CARB toroidal roller bearings in minutes.

Learn about the design, construction, advantages, and applications of these versatile bearings used in wind turbines, mining equipment, and paper mills.

Discover why they are the best choice for heavy-duty industrial equipment with a long service life of up to 20 years

CARB toroidal roller bearings are a reliable and versatile choice for heavy-duty industrial equipment, thanks to their ability to handle high radial loads, accommodate misalignment and have a long service life.

They are commonly used in wind turbines, mining equipment, and paper mills.

CARB toroidal roller bearings are essential in a wide range of industrial equipment and machinery.

These bearings are known for their reliability and longevity, from wind turbines to mining equipment.

Dive deeper into this comprehensive guide and discover all the features that make CARB toroidal roller bearings the best choice for your application.

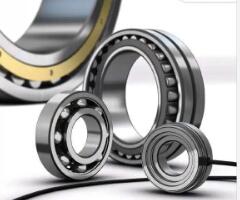

What is CARB toroidal roller bearings

CARB toroidal roller bearings are self-aligning bearings that offer complete interchangeability with any other self-aligning ball bearing, cylindrical roller bearing, or spherical roller bearing with the same boundary conditions.

They adhere to ISO 15:1998 standards. The acronym CARB stands for "compact aligning roller bearing,"

These bearings combine the advantages of cylindrical roller bearings, needle roller bearings, and spherical roller bearings into one type.

Toroidal bearings are designed to tolerate axial displacement, angular misalignment, and high load capacity.

A CARB bearing has a convex profile and one row of barrel-shaped symmetric rollers sandwiched between two raceways.

This low-friction, high-load roller bearing is self-aligning and has a long service life, reducing the maintenance required.

These bearings are commonly used in various industries such as metals, pulp and paper, mining, mineral processing, and marine and industrial transmissions.

They are also suitable for reducing noise and vibration due to their ability to withstand misalignment and displacement.

Design and Construction

CARB toroidal roller bearings are designed with a convex profile, one row of barrel-shaped symmetric rollers, and two raceways.

The rollers are typically made of high-quality steel and are specially heat-treated to ensure maximum strength and durability.

The raceways are also typically made of high-quality steel and are precision-ground to ensure a smooth and accurate fit.

The bearing's design allows for self-alignment, which means it can compensate for slight misalignments in the shaft or housing without affecting the bearing's performance.

Additionally, the toroidal shape of the rollers reduces friction and increases the bearing's load-carrying capacity.

CARB toroidal roller bearings vs. traditional roller bearings:

1.Self-aligning: CARB toroidal roller bearings are self-aligning, which means they can compensate for slight misalignments in the shaft or housing without affecting the bearing's performance.

Traditional roller bearings are not self-aligning and require proper alignment to function correctly.

2.Toroidal shape: The rollers in CARB toroidal roller bearings are toroidal in form, which reduces friction and increases the bearing's load-carrying capacity.

Traditional roller bearings typically have cylindrical rollers.

3.Interchangeability: CARB toroidal roller bearings offer complete identity with any other self-aligning ball bearing, cylindrical roller bearing, or spherical roller bearing with the same boundary conditions.

Traditional roller bearings are not interchangeable.

4.Toroidal bearings are more tolerant to axial displacement, angular misalignment, and high load capacity than traditional roller bearings.

5.Toroidal bearings are more versatile and can be used in a wide range of applications, while traditional roller bearings are limited to specific uses.

Characteristics of CARB toroidal roller bearings, such as self-aligning and high radial load capacity

1.Self-aligning:One of the main characteristics of CARB toroidal roller bearings is that they are self-aligning.

This means that the bearing can compensate for slight misalignments in the shaft or housing without affecting the bearing's performance.

This feature makes them ideal for applications where misalignment is likely to occur.

2.High radial load capacity:CARB toroidal roller bearings can handle high radial loads, making them suitable for heavy-duty applications.

The toroidal shape of the rollers reduces friction and increases the bearing's load-carrying capacity.

3.Low friction:The toroidal shape of the rollers also reduces friction, which improves the bearing's efficiency and extends its service life.

4.High precision:CARB toroidal roller bearings are precision-ground to ensure a smooth and accurate fit.

This improves the bearing's performance and extends its service life.

5.Durable:The rollers in CARB toroidal roller bearings are typically made of high-quality steel and are specially heat-treated to ensure maximum strength and durability.

6.Interchangeability: CARB toroidal roller bearings offer complete identity with any other self-aligning ball bearing, cylindrical roller bearing, or spherical roller bearing with the same boundary conditions.

7.Tolerance to axial displacement and angular misalignment:Toroidal bearings are more tolerant to axial displacement, angular misalignment, and high load capacity than traditional roller bearings, which makes them suitable for use in a wide range of applications.

Components of CARB toroidal roller bearings, such as the inner ring, outer ring, rollers, and cage

1.Inner ring:The inner ring is the component that sits on the shaft or housing and rotates with it.

It is typically made of high-quality steel and is precision-ground to ensure a smooth and accurate fit.

2.Outer ring: The outer ring sits on the housing or support structure and does not rotate.

It is also typically made of high-quality steel and is precision-ground to ensure a smooth and accurate fit.

3.Rollers are cylindrical or toroidal-shaped elements that sit between the inner and outer rings.

They are typically made of high-quality steel and are specially heat-treated to ensure maximum strength and durability.

4.Cage:The cage, also called the separator, is the component that holds the rollers in place and guides them as they rotate between the inner and outer rings.

The cage is typically made of plastic or metal and is designed to minimize friction between the rollers and the rings.

5.Lubricant:Some bearings have lubricant inside to reduce friction and the wear of the components.

All these components support and guide the shaft or housing, allowing it to rotate smoothly and efficiently with minimal friction and wear.

This combination of features makes CARB toroidal roller bearings suitable for various applications, including heavy-duty industrial equipment, power transmission systems, and other machinery.

Advantages of CARB toroidal roller bearings

1.Increased reliability and longevity:CARB bearings are designed to have a long service life, with a special roller profile that prevents stress peaks at the roller ends and improved wear resistance.

These features reduce the need for frequent maintenance and repairs, increasing the overall reliability and longevity of the bearing.

2.Improved performance in misaligned or high-load conditions:CARB bearings are self-aligning, which allows them to accommodate misalignment and axial displacement,

making them suitable for use in high-load and misaligned conditions.

3.Reduced maintenance requirements:The low friction of CARB bearings and the self-guiding rollers keep friction and frictional heat at low levels,

which reduces the wear and tear on the bearing components and extends the life of the lubricant.

Additionally, the long service life of CARB bearings reduces the need for frequent maintenance and repairs, further reducing maintenance requirements.

4.Wide assortment of dimension series:CARB bearings are available with the same boundary dimensions as corresponding spherical roller bearings,

self-aligning ball bearings, cylindrical roller bearings, and needle roller bearings, which makes them suitable for use in a wide range of applications.

5.Long bearing system life:CARB bearings provide benefits in self-aligning bearing arrangements; with a CARB bearing in the non-locating position,

there are no internally induced axial forces, which results in multiple benefits like less load extends the service life, the bearings run cooler,

the lubricant lasts longer, and maintenance intervals can be extended, noise and vibration levels can be reduced.

Applications

1.Wind turbines: CARB toroidal roller bearings are commonly used in wind turbines due to their ability to handle high radial loads and tolerate misalignment.

They are used in the wind turbine's main shaft, gearbox, and generator to ensure smooth and efficient operation.

2.Mining equipment: CARB toroidal roller bearings are also commonly used in mining equipment such as conveyors, crushers, and grinding mills.

They can handle the heavy loads, and harsh conditions found in mining operations and are resistant to dust and debris.

3.Paper mills:CARB toroidal roller bearings are used in paper mills to support heavy rolls of paper and reduce machinery's noise and vibration levels.

They are commonly used in the paper mill's calender rolls and press rolls.

4.Industrial transmissions: CARB toroidal roller bearings are also used in industrial transmissions, such as gearboxes, reducers, and conveyors.

They can handle high radial loads and tolerate misalignment, which makes them suitable for use in these applications.

5.Marine Industry: CARB toroidal roller bearings are suitable for use in marine applications, such as in propulsion systems, steering gear, and deck cranes.

They can withstand harsh marine environments and provide a long service life.

6.Construction machinery:CARB toroidal roller bearings are suitable for construction machineries, such as excavators, bulldozers, cranes, and other heavy equipment.

They can handle high radial loads and tolerate misalignment, which makes them suitable for use in these applications.

7.Other Applications:they can be used in many other applications, such as machine tools, pumps, fans and compressors, and other heavy machinery.

Overall, the versatility of CARB toroidal roller bearings makes them suitable for use in a wide range of industries and applications.

Their ability to handle high radial loads and tolerate misalignment, combined with their long service life and low maintenance requirements, makes them an ideal choice for many types of machinery and equipment.

Conclusion

CARB toroidal roller bearings are reliable and versatile for heavy-duty industrial equipment.

With their ability to handle high radial loads, tolerate misalignment, and have a long service life, they are an ideal choice for wind turbines, mining equipment, and paper mills.

Use this guide to understand the advantages of using CARB toroidal roller bearings in your application.