Choosing the Right Deep Groove Ball Bearings for Your Application

Looking for guidance on how to choose the right deep-groove ball bearings for your application?

Look no further! This comprehensive guide will provide you with all the information you need to make an informed decision,

including factors to consider, types of bearings available, and tips for proper installation and maintenance.

Start optimizing your machinery's performance today!

Deep groove ball bearings are a critical component in many industrial applications, ranging from motors and generators to pumps and compressors.

With so many options available, choosing the right bearings for your machinery can be a daunting task.

However, selecting the appropriate bearing can significantly impact the performance, longevity, and reliability of your equipment.

In this article, we'll provide you with a comprehensive guide to choosing the right deep-groove ball bearings for your application. Read on to learn more.

Choosing the right deep-groove ball bearings for your application involves considering several factors to ensure optimal performance, reliability, and longevity.

Here are some key steps to guide you:

1.Determine the load requirements: Identify the load requirements of your application, including the magnitude and direction of forces acting on the bearing.

This information will help you choose the appropriate bearing size and type.

2.Consider the speed requirements: Determine the required rotational speed of the bearing and select a bearing with a suitable speed rating that can handle the expected speed range.

3.Evaluate the operating conditions: Consider the operating environment, including temperature, humidity, and the presence of contaminants or corrosive substances.

Choose a bearing with appropriate sealing and lubrication features that can withstand these conditions.

4.Determine the shaft and housing requirements: Choose a bearing that matches the shaft and housing dimensions and fits securely without causing excessive wear or damage.

5.Choose the appropriate bearing type: Deep-groove ball bearings come in various types, including single-row, double-row, and angular contact bearings.

Choose the appropriate type that meets the specific load and speed requirements of your application.

6.Ensure proper installation and maintenance: Proper installation and maintenance are crucial for the optimal performance and longevity of deep-groove ball bearings.

Follow manufacturer guidelines for installation, lubrication, and maintenance to ensure trouble-free operation.

By considering these factors and following the appropriate steps,

you can choose the right deep-groove ball bearings for your application and optimize your equipment's performance and reliability.

In this comprehensive guide, we have covered the essential factors to consider when selecting deep groove ball bearings,

including load and speed requirements, operating conditions, shaft and housing dimensions, bearing types, and installation and maintenance practices.

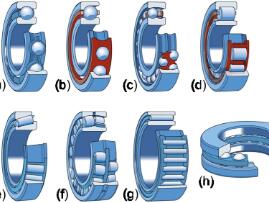

Types of Deep Groove Ball Bearings

Open Type

An open-type deep groove ball bearing is a type of bearing that has no seals or shields and is open on both sides.

This means that the balls and inner and outer races are exposed to the environment, making them more susceptible to contamination and damage from debris, dirt, and moisture.

However, open-type bearings are often preferred in applications where the bearings are regularly cleaned or lubricated, or where low torque and high speeds are required.

Additionally, they can provide better heat dissipation than sealed or shielded bearings.

Open-type deep groove ball bearings are commonly used in industrial machinery, automotive applications, and other high-speed and high-temperature environments.

Sealed Type

A sealed-type deep groove ball bearing is a type of bearing that has seals on both sides of the bearing.

The seals are typically made of rubber or plastic and protect against contamination and moisture by forming a barrier around the balls and races.

Sealed-type bearings are ideal for applications where the bearing is exposed to heavy contamination or where a clean operating environment is critical.

They can also retain lubricant within the bearing, reducing the need for maintenance and prolonging the bearing's lifespan.

Sealed-type deep groove ball bearings are available in a variety of seal types, including contact seals, non-contact seals, and low-friction seals.

These bearings are commonly used in applications such as electric motors, automotive systems, and industrial machinery, where reliability and longevity are crucial.

Shielded Type

A shielded-type deep groove ball bearing is a type of bearing that has shields or protective covers on one or both sides of the bearing.

The shields are typically made of metal or rubber and protect against contamination and debris by forming a barrier around the balls and races.

The shields also help retain the lubricant within the bearing and prevent leakage.

Shielded-type bearings are commonly used in applications where the bearing is exposed to moderate to heavy contamination or where a cleaner operating environment is required.

They can also be suitable for applications with lower speeds and lower torque requirements.

Shielded-type deep groove ball bearings are available in a variety of shield types, such as single metal shields, double metal shields, and non-contact rubber seals, among others.

Snap Ring Type

A snap ring type deep groove ball bearing is a type of bearing that has a retaining ring or snap ring installed on the outer ring of the bearing.

The snap ring is a circular metal ring that fits into a groove on the outer diameter of the bearing's outer ring, holding it in place axially.

This design allows for easy assembly and disassembly of the bearing and can simplify the overall design of the application.

Snap ring-type deep groove ball bearings are commonly used in applications where there is a need for the axial location of the bearing, such as in gearboxes, transmissions, and other power transmission systems.

They are also suitable for applications that require frequent disassembly or maintenance, as the snap ring allows for quick and easy removal of the bearing from the shaft.

Flanged-Type

A flanged type deep groove ball bearing is a type of bearing that has a flange attached to one or both sides of the outer ring.

The flange is a flat or raised rim that provides additional support and stability to the bearing and facilitates mounting in the application.

Flanged-type bearings are commonly used in applications where space is limited or where a precise location of the bearing is required, such as in electric motors, pumps, and conveyors.

They can also simplify the overall design of the application by eliminating the need for additional components to support the bearing.

Flanged-type deep groove ball bearings are available in various flange shapes and sizes, including round, square, and oval, among others, to fit a wide range of applications.

Extended Inner Ring Type

An extended inner ring type deep groove ball bearing is a type of bearing that has an extended inner ring on one side of the bearing.

The extended inner ring provides additional support to the bearing and facilitates mounting in the application.

This design can help to simplify the overall design of the application by eliminating the need for additional components to support the bearing.

Extended inner ring type bearings are commonly used in applications where space is limited,

or where a precise location of the bearing is required, such as in conveyor systems, food processing equipment, and textile machinery.

They can also help to accommodate misalignment between the shaft and housing.

Extended inner ring type deep groove ball bearings are available in various sizes and configurations to fit a wide range of applications.

Maximum Capacity Type

A maximum capacity type deep groove ball bearing is a type of bearing that has a larger number of balls than standard deep groove ball bearings.

This design allows for higher radial load-carrying capacity, making them suitable for applications where heavy loads and high speeds are present.

Maximum capacity type bearings are commonly used in high-load applications such as electric motors, pumps, and compressors, where the bearing must withstand heavy loads without sacrificing speed or reliability.

These bearings have a filling slot in the outer race that allows for additional balls to be added, increasing the bearing's load-carrying capacity.

The maximum capacity type deep groove ball bearing is available in various sizes, including both metric and imperial sizes, to fit a wide range of applications.

Angular Contact Type

An angular contact type deep groove ball bearing is a type of bearing that is designed to accommodate both radial and axial loads by allowing the races to be angled relative to each other.

This design allows for higher axial load carrying capacity than standard deep groove ball bearings and can handle both thrust and radial loads simultaneously.

Angular contact-type bearings have a specific contact angle between the inner and outer races, which determines the level of axial load-carrying capacity.

These bearings are commonly used in high-speed applications such as machine tool spindles, pumps, and turbines, where precise positioning and high accuracy are required.

They are also suitable for applications where there are significant axial loads present, such as in automotive steering systems and gearboxes.

Angular contact-type deep groove ball bearings are available in various configurations and sizes to fit a wide range of applications.

Factors to Consider When Choosing Deep Groove Ball Bearings

There are several factors to consider when choosing deep groove ball bearings for your application:

1.Load capacity: Consider the magnitude and direction of the loads the bearing will be subjected to. Choose a bearing that can handle the maximum load capacity of the application.

2.Speed capability: Determine the required speed of the bearing and choose a bearing with a suitable speed rating that can handle the expected speed range.

3.Operating conditions: Consider the operating environment, including temperature, humidity, and the presence of contaminants or corrosive substances.

Choose a bearing with appropriate sealing and lubrication features that can withstand these conditions.

4.Shaft and housing fit: Choose a bearing that matches the shaft and housing dimensions and fits securely without causing excessive wear or damage.

5.Accuracy and precision requirements: Consider the level of accuracy and precision required for the application and choose a bearing that meets these requirements.

6.Maintenance requirements: Consider the maintenance requirements of the bearing and choose a bearing that can be easily maintained and serviced.

7.Cost: Consider the cost of the bearing and the total cost of ownership over its expected lifespan.

By considering these factors, you can choose the appropriate deep groove ball bearing that meets your application's specific requirements and ensure optimal performance and reliability.

Conclusion

In conclusion, choosing the right deep groove ball bearings for your application is crucial for ensuring optimal equipment performance, reliability, and longevity.

By considering the load requirements, speed capability, operating conditions, shaft and housing fit, accuracy and precision requirements, maintenance requirements,

and cost, you can select the appropriate bearing that meets your application's specific needs.

Remember to follow manufacturer guidelines for installation, lubrication, and maintenance to ensure trouble-free operation.

By choosing the right deep groove ball bearings for your application, you can achieve optimal performance, reliability, and cost-effectiveness for your equipment.