Can ball bearing take the axial load?

Discover if ball bearings can handle axial loads. Learn about types, differences, factors, and alternatives.

Ensure optimal performance.

Ball bearings are widely used in various mechanical applications because they reduce friction and support the rotational and linear motion.

However, when it comes to axial load, there is a need to understand the capabilities and limitations of ball bearings.

Can ball bearings take the axial load?

Yes, ball bearings can take axial loads to a certain extent.

However, the magnitude of the axial load that a ball bearing can handle depends on several factors,

including the bearing type, design, preload, lubrication, and operating conditions.

This article explores whether ball bearings can handle axial loads, compare different types of ball bearings,

explain the differences between radial and axial loads,

discuss the factors influencing ball bearings' ability to handle axial loads and explore alternative bearing options for axial load applications.

What is Axial Load?

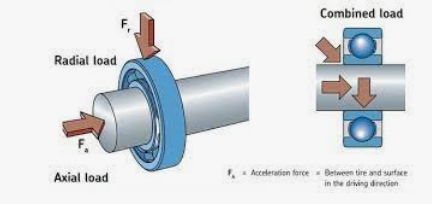

Axial load refers to the force applied parallel to the bearing's axis of rotation or linear motion.

It is commonly encountered in applications where there is a need for thrusting, pushing, or pulling.

Axial loads differ from radial loads, which are forces applied perpendicular to the bearing's axis.

Types of Ball Bearings:

2.1 Overview of Different Types of Ball Bearings:

Deep Groove Ball Bearings:These are the most common type of ball bearings designed to handle primarily radial loads.

They have a simple design with deep raceways that allow the balls to roll smoothly.

Angular Contact Ball Bearings:Angular contact ball bearings are designed to handle radial and axial loads.

They have contact angles supporting higher axial loads than deep groove ball bearings.

The contact angle helps distribute the load between the balls and the raceways.

Thrust Ball Bearings: Thrust ball bearings are designed to handle predominantly axial loads.

They have flat raceways and can accommodate axial loads in a single direction.

Thrust ball bearings are commonly used in automotive transmissions and machine tool spindles.

Self-Aligning Ball Bearings: Self-aligning ball bearings are designed to accommodate misalignment between the shaft and the housing.

While they are primarily used to handle radial loads, they can also handle limited axial loads.

2.2 Comparison of Each Type's Capabilities for Handling Axial Loads:

While all ball bearings can handle some degree of axial load, the magnitude of the load they can withstand varies among different types.

Angular contact ball bearings and thrust ball bearings are specifically designed to handle higher axial loads compared to deep grooves and self-aligning ball bearings.

Angular ball bearings have larger contact angles, allowing them to distribute axial loads more efficiently.

Thrust ball bearings, conversely, have flat raceways and can handle higher axial loads due to their design.

It is important to consider the application's specific requirements to select the most suitable type of ball bearing.

Radial Load vs. Axial Load:

3.1 Explanation of Radial Load and Axial Load:

Radial load refers to the force applied perpendicular to the bearing's axis, causing the inner and outer races of the bearing to deform.

This type of load is common in applications where rotational motion is required, such as electric motors or wheels.

Axial load, on the other hand, is applied parallel to the bearing's axis and can cause the balls to move along the raceway. Axial loads are encountered in applications with thrust or linear forces, such as pumps, compressors, or axial fans.

3.2 Differences between How a Ball Bearing Handles Radial vs. Axial Load:

Ball bearings are primarily designed to handle radial loads efficiently.

The balls in the bearing roll between the inner and outer races, distributing the load evenly.

The contact between the balls and the raceways minimizes friction and enables the bearing to rotate smoothly.

When subjected to axial loads, the behavior of ball bearings differs from that under radial loads.

Axial loads can cause the balls to move sideways along the raceway, leading to increased friction and potential failure of the bearing.

This phenomenon is known as "skidding" or "sliding" and can result in excessive wear, overheating, and premature bearing failure.

To mitigate the effects of axial loads, manufacturers employ various design features in ball bearings.

Angular contact ball bearings and thrust ball bearings are designed with specific contact angles and raceway configurations to better handle axial loads.

The contact angle helps to distribute the load between the balls and the raceways more evenly,

reducing skidding and improving the bearing's ability to handle axial forces.

Ball Bearings and Axial Load:

4.1 Can Ball Bearings Take Axial Load?

Yes, ball bearings can take axial loads to a certain extent.

However, the magnitude of the axial load that a ball bearing can handle depends on several factors,

including the bearing type, design, preload, lubrication, and operating conditions.

4.2 Factors That Determine the Ability of a Ball Bearing to Handle Axial Load:

Bearing Type:As mentioned earlier, angular contact and thrust ball bearings are better suited for handling higher axial loads than deep grooves and self-aligning ball bearings.

These bearings' design and contact angles enable them to withstand greater axial forces.

Design and Construction: The design and construction of the ball bearing also play a crucial role in its ability to handle axial loads.

Bearings with more contact points, larger balls, and optimized raceway profiles can distribute axial loads more effectively,

reducing the risk of skidding and improving load-carrying capacity.

Preload:Preload is the intentional introduction of internal clearance reduction in a bearing to enhance its ability to handle axial loads.

Applying a preload to the bearing eliminates internal clearances, improving rigidity and load distribution.

This can be achieved through axial compression of the bearing components during assembly.

Lubrication:Proper lubrication is essential for the smooth operation and longevity of ball bearings under axial loads.

Adequate lubrication reduces friction and heat generation, improving the bearing's ability to withstand axial forces.

It is crucial to use lubricants recommended by the bearing manufacturer and to ensure proper lubrication intervals.

Operating Conditions:The operating conditions of an application can significantly impact the performance of ball bearings under axial loads.

Factors such as rotational speed, temperature, shock loads, and contaminants can affect the bearing's ability to handle axial forces.

Considering these factors and selecting suitable bearings for the specific operating conditions is important.

Alternatives to Ball Bearings:

Thrust Bearings:Thrust bearings are designed to handle high axial loads.

They come in various configurations, such as thrust roller bearings, thrust spherical roller bearings, and thrust tapered roller bearings.

These bearings can accommodate both thrust and radial loads and are often used in automotive transmissions,

machine tool spindles, and heavy machinery applications.

Tapered Roller Bearings: Tapered roller bearings can handle radial and axial loads.

They are designed with tapered inner and outer races that support high axial loads.

Tapered roller bearings are commonly used in applications with both types of loads,

such as automotive wheel hubs and heavy-duty industrial machinery.

Cylindrical Roller Bearings:Cylindrical roller bearings can handle higher axial loads than ball bearings.

They have cylindrical rollers designed to accommodate heavy radial and axial loads.

Cylindrical roller bearings are commonly used in applications such as rolling mills, gearboxes, and large industrial machinery.

Spherical Roller Thrust Bearings:Spherical roller thrust bearings are designed to handle extremely high axial loads.

They have a spherical raceway in the housing washer and a self-aligning capability to compensate for misalignment.

These bearings are suitable for applications with heavy axial and moderate radial loads, such as heavy-duty machinery and mining equipment.

Conclusion:

Understanding the capabilities and limitations of ball bearings in handling axial loads is crucial for selecting the right bearing for specific applications.

By considering factors like bearing type, design, and operating conditions, engineers can ensure optimal performance and reliability while minimizing the risk of premature failure.

Explore alternative bearing options when necessary to meet high axial load requirements effectively.