Maximizing Efficiency with High-Quality Deep Groove Ball Bearings

Increase productivity with top-notch deep groove ball bearings.

Maximize efficiency, and reduce downtime & maintenance costs.

Learn more now.

When it comes to maximizing efficiency and productivity, having reliable and high-quality components is crucial. In this article,

we'll explore the benefits of using top-notch deep groove ball bearings and how they can help you get the most out of your machinery.

High-quality deep groove ball bearings can handle both radial and axial loads, reducing downtime and maintenance costs.

By using top-notch deep groove ball bearings, you can increase the overall efficiency of your equipment,

minimize the risk of equipment failure, increase uptime, and achieve optimal performance.

High-quality deep groove ball bearings can help you achieve maximum efficiency and productivity.

Learn more about the benefits of using high-quality deep groove ball bearings in this article.

Introduction

A. Explanation of the importance of high-quality deep groove ball bearings

High-quality deep groove ball bearings are designed and manufactured to exacting standards, ensuring reliable and consistent performance over the long term.

These bearings can handle high loads, resist wear and tear, and operate at high speeds, making them ideal for demanding applications.

By investing in high-quality deep groove ball bearings, you can ensure the smooth and efficient operation of your machinery.

These bearings can help you minimize downtime, reduce maintenance costs, and improve productivity, ultimately leading to increased profitability and a competitive edge in your industry.

B. Purpose of the outline: to demonstrate how using high-quality deep groove ball bearings can maximize efficiency

The purpose of the outline is to provide a structured and organized overview of the key points and arguments that support the idea that using high-quality deep groove ball bearings can maximize efficiency in industrial and mechanical applications.

The outline can help to establish a clear and logical flow of ideas, and it can also help to identify gaps or areas where more information or research may be needed.

Overall, the outline serves as a roadmap for the article, helping to guide the writing process and ensuring that the final product is cohesive, informative, and persuasive.

What are Deep Groove Ball Bearings?

A. Explanation of deep groove ball bearings

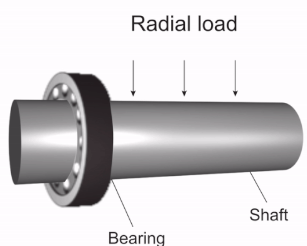

Deep groove ball bearings are a type of rolling-element bearing that consists of an inner ring, an outer ring, a cage, and a set of balls that are located between the rings.

These bearings are designed to handle both radial and axial loads, and they are commonly used in a wide range of industrial and mechanical applications.

B. Parts and functionality

The inner and outer rings of the bearing are typically made of high-quality steel or other materials that are chosen for their strength,

durability, and resistance to wear and tear.

The balls are also typically made of steel or ceramic, and they are carefully designed and manufactured to be perfectly round and smooth,

which helps to reduce friction and improve performance.

The cage, which is often made of brass or other materials, helps to keep the balls evenly spaced and prevent them from rubbing against each other.

This ensures that the bearings operate smoothly and quietly, even at high speeds.

C. Comparison with other types of bearings

When it comes to bearings, there are several different types available, each with its advantages and disadvantages.

Here is a brief comparison of deep groove ball bearings with some other common types of bearings:

-Angular Contact Ball Bearings: These bearings are similar to deep groove ball bearings but are designed to handle more axial loads.

They are commonly used in applications such as machine tools and pumps.

-Spherical Roller Bearings: These bearings are designed to handle very heavy radial loads and some axial loads.

They are often used in applications such as mining and construction equipment.

-Tapered Roller Bearings: These bearings are designed to handle both radial and axial loads and are often used in automotive applications.

They can handle high loads and are resistant to wear and tear.

Advantages of Using High-Quality Deep Groove Ball Bearings

A. Longer Lifespan

High-quality deep groove ball bearings have a longer lifespan than inferior or substandard bearings.

This is because high-quality bearings are designed and manufactured to exacting standards using high-quality materials, which ensures that they are more durable and resistant to wear and tear.

The longer lifespan of high-quality deep groove ball bearings means that they can provide reliable and consistent performance over the long term,

reducing downtime and maintenance costs, and ultimately leading to increased productivity and profitability for the user.

B. Increased Load Capacity

High-quality deep groove ball bearings have an increased load capacity compared to inferior or substandard bearings.

This is because high-quality bearings are designed and manufactured to exacting standards using high-quality materials,

which ensures that they can withstand higher loads and stresses without deformation or failure.

The increased load capacity of high-quality bearings is achieved through careful design of the raceways and ball size,

High-quality deep groove ball bearings that can operate at higher speeds offer several advantages,

including reduced friction and heat generation, increased accuracy and precision, increased productivity, and lower maintenance costs.

These benefits make them ideal for use in various high-speed applications across different industries.

D. Reduced Maintenance and Downtime

High-quality deep groove ball bearings are designed to minimize friction and wear, which is essential for high-speed applications.

They have advanced lubrication systems and seals that prevent contamination and reduce wear and tear, resulting in lower maintenance requirements.

High-quality deep groove ball bearings undergo extensive quality control checks to ensure they meet industry standards and regulations.

They have fewer defects and are less prone to failure, reducing the need for maintenance and the risk of unplanned downtime.

E. Cost-Effective

High-quality deep groove ball bearings are less prone to failure and defects,

reducing the risk of accidents and improving safety in the workplace.

This can result in lower insurance costs and other related expenses.

How to Choose High-Quality Deep Groove Ball Bearings

A. Identifying the needs and requirements of your machinery

To choose high-quality deep groove ball bearings for your machinery,

you need to identify the needs and requirements of your machinery. Here are the steps you can follow:

-You need to determine the load and speed requirements of your machinery.

The load and speed rating of a bearing must match or exceed the requirements of your machinery.

-You need to consider the operating environment of your machinery, including temperature, moisture, and contaminants such as dirt, dust, and chemicals.

This will help you choose the appropriate bearing material and seal design.

-You need to determine the fit and clearance requirements of your machinery.

A proper fit and clearance will ensure that the bearing operates efficiently and with minimal noise and vibration.

B. Understanding the different types of bearings and their specifications

Deep groove ball bearings can be made of various materials, such as stainless steel or ceramic, depending on the application requirements.

The bearing's design, such as the number of balls and the cage material, can also affect its load capacity and speed rating.

Check the manufacturer's catalog to ensure that the bearing's dimensions and tolerances meet your machinery's requirements.

The bearing's fit and clearance can affect its performance, noise level, and lifespan.

C. Evaluating the supplier's quality standards

Here are some factors to consider when evaluating a supplier's quality standards:

-Look for suppliers that have industry certifications such as ISO 9001 or other quality management systems.

These certifications indicate that the supplier has implemented quality management systems that ensure consistent quality and reliability.

-Suppliers should have a traceability system in place that allows them to track the origin and history of each bearing.

This system should be able to provide information such as the material composition, manufacturing date, and testing results.

-Suppliers should perform various tests to ensure that the bearings meet industry standards and application requirements.

These tests may include material composition analysis, hardness testing, dimensional inspections, and fatigue testing.

-Suppliers should have a robust inspection process that verifies the quality of each bearing.

This process should include visual inspection, dimensional inspection, and functional testing.

-Suppliers should provide documentation that includes material certifications, test reports, and inspection reports.

These documents should be available upon request and demonstrate the supplier's commitment to quality.

Applications of High-Quality Deep Groove Ball Bearings

A. Industrial Machinery

High-quality deep groove ball bearings have a wide range of applications in industrial machinery including in electric motors, machine tools such as lathes,

milling machines, grinders, pumps and compressors, conveyor systems such as baggage handling systems, food processing equipment,

and material handling equipment, and agricultural equipment such as combines, tractors, and tillers.

B. Automotive Industry

High-quality deep groove ball bearings are commonly used in the automotive industry for various applications including wheel bearings in vehicles,

alternators to support the rotor and provide smooth rotation, air conditioning compressors to support the compressor shaft and provide smooth rotation,

water pumps to support the impeller, steering systems, and transmission systems to support the gears.

C. Medical Equipment

High-quality deep groove ball bearings are used in a variety of medical equipment applications including in medical imaging equipment such as CT scanners and MRI machines,

surgical equipment such as power tools, drills, and saws, laboratory equipment such as centrifuges, shakers,

and mixers, dental equipment such as dental drills and handpieces, and in prosthetic devices to provide smooth and precise rotation.

D. Aerospace

High-quality deep groove ball bearings are used in a variety of aerospace applications including jet engines to support the rotating components such as the fan,

compressor, turbine, landing gear,

and various actuators on aircraft such as flap actuators, spoiler actuators, and landing gear actuators, helicopter rotor systems,

and satellite applications such as antenna positioning systems and solar array tracking systems.

Installation and Maintenance of High-Quality Deep Groove Ball Bearings

A. Proper installation procedures

Here are the proper installation procedures:

-Before installation, ensure that the bearing and surrounding components are clean and free from any debris or contaminants.

-Apply the appropriate amount and type of lubrication to the bearing before installation to ensure smooth operation and prevent premature wear.

-Ensure that the bearing is the correct size and has the correct fit for the application.

The bearing should fit snugly in the housing but should not be forced.

-Ensure that the bearing is properly aligned with the shaft and housing.

Misalignment can cause premature wear and damage to the bearing.

-Follow the recommended torque specifications for tightening the bearing to the shaft and housing.

Over-tightening can cause damage to the bearing, while under-tightening can cause the bearing to become loose.

-After installation, test the bearing for proper operation and check for any unusual noise or vibration.

B. Routine maintenance and inspection

Routine maintenance and inspection of high-quality deep groove ball bearings are essential to ensure optimal performance and prevent premature failure.

Some basic maintenance and inspection procedures include checking for proper lubrication,

monitoring for unusual noise or vibration, checking for proper alignment, and monitoring for signs of wear or damage.

C. Troubleshooting common problems

Troubleshooting steps may include checking for proper lubrication and alignment,

inspecting for damage or wear, and identifying the source of excessive load or vibration.

Addressing these issues promptly can help prevent further damage and prolong the lifespan of the bearing.

Conclusion

Investing in high-quality deep groove ball bearings can significantly increase the efficiency and productivity of your equipment.

So, don't compromise on quality when it comes to your machinery – choose reliable deep groove ball bearings for maximum efficiency.