Understanding Bearing Fit Tolerance: A Comprehensive Guide

Learn everything about bearing fit tolerance in our comprehensive guide.

Discover how to ensure proper fits and avoid costly errors.

When it comes to bearings, choosing the right fit tolerance is crucial for ensuring optimal performance and longevity.

In this comprehensive guide, we'll take a deep dive into bearing fit tolerance,

exploring the different types of fits, how to calculate them, and what factors to consider when selecting the right fit for your application.

Bearing fit tolerance is a critical factor in determining the optimal performance and lifespan of a bearing.

The fit must strike a balance between being not too loose or not too tight to avoid costly errors.

A fit that is too loose can result in excessive wear and noise, while a fit that is too tight can cause overheating and premature failure.

Whether you're a seasoned engineer or a beginner,

this guide will provide you with the knowledge and tools you need to ensure your bearings operate smoothly and efficiently.

What is bearing fit tolerance?

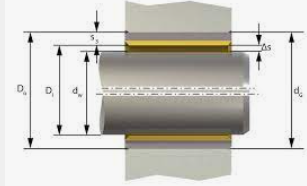

Bearing fit tolerance refers to the allowable variation in the size and shape of mating parts that make up a bearing assembly.

It determines the amount of interference or clearance between the bearing and its housing or shaft.

The right fit tolerance is critical for ensuring optimal performance, longevity, and reliability of the bearing system.

A fit that is too loose can lead to excessive vibration, noise, and premature wear, while a fit that is too tight can cause overheating,

binding, and early failure. Bearing fit tolerance is determined based on various factors such as operating conditions, load, speed, and type of bearing.

Types of Bearing Fit Tolerance

Clearance fit

A clearance fit is a type of bearing fit tolerance where the shaft is smaller than the bore of the bearing or housing.

This results in a gap or clearance between the two mating parts.

A clearance fit is commonly used when the bearing is required to operate at high speeds or temperatures or when the shaft undergoes thermal expansion.

It allows for easy assembly and disassembly of the bearing system and can accommodate slight misalignments between the shaft and housing.

Interference fit

An interference fit is a type of bearing fit tolerance where the shaft is larger than the bore of the bearing or housing.

This results in a press fit where the bearing is compressed and firmly held in place.

An interference fit is commonly used when high precision is required or when the bearing is subjected to high loads or vibrations.

It provides excellent stability, prevents slippage or rotation, and minimizes axial movement.

Transition fit

A transition fit is a type of bearing fit tolerance where the shaft is slightly larger than the bore of the bearing or housing,

resulting in a tight but movable fit. This fit tolerance is used when a balance between clearance and interference is needed.

A transition fit can provide the benefits of both clearance and interference fits, such as ease of assembly and disassembly, as well as stability and reduced vibration.

This type of fit can be suitable for applications where there are variable operating conditions or where high precision and low vibration are required.

Factors Affecting Bearing Fit Tolerance

Temperature

When temperatures increase, materials tend to expand, which can cause the bearing to expand as well.

Load

When a bearing is subjected to a load, the material can deform, causing a change in shape and dimension.

Speed

High speeds can cause heat buildup and thermal expansion, which can affect the fit tolerance of the bearing.

It is important to choose a fit tolerance that accommodates the expected operating speeds to prevent overheating and premature wear.

Lubrication

Adequate lubrication is essential for reducing friction and wear, and ensuring proper performance and longevity of the bearing.

The type of lubricant used can also affect the fit tolerance of the bearing, as some lubricants can cause swelling or shrinkage of the bearing material.

Surface finish

The surface finish of the shaft, housing, and bearing components can affect the fit tolerance and can also impact the level of friction, wear, and noise generated by the bearing.

Misalignment

Misalignment between the shaft and housing can cause additional stress and wear on the bearing, affecting the fit tolerance and reducing its performance and lifespan.

Shaft/housing material

The type of material used for the shaft, housing, and bearing components can affect the fit tolerance,

as different materials have different coefficients of thermal expansion and can expand or contract at different rates under load or temperature changes.

Impact on bearing life and performance

Extreme impact or shock loads can cause permanent deformation or damage to the bearing and affect the fit tolerance.

Choosing the appropriate fit tolerance and material can help minimize the risk of damage due to impact or shock loads.

How to Select the Right Bearing Fit Tolerance

Determining required fit tolerance based on application requirements

Here are some general guidelines to help determine the required fit tolerance based on application requirements:

-For high-speed applications, a clearance fit tolerance is typically recommended to minimize friction and reduce heat buildup.

-For high-load applications, an interference fit tolerance is often required to provide the necessary stability and support.

-For applications with variable loads,

a transition fit tolerance may be suitable to accommodate the varying conditions and balance the need for clearance and interference.

-For high-temperature applications,

an interference fit tolerance is often necessary to prevent the bearing from seizing due to thermal expansion.

-For low-temperature applications,

a clearance fit tolerance is usually preferred to prevent the bearing from binding due to thermal contraction.

-For misaligned shafts or housings,

a clearance fit tolerance is often recommended to allow for movement and compensate for misalignment.

-For applications with high levels of impact or shock loads,

a tighter interference fit tolerance may be required to prevent the bearing from shifting or slipping under load.

It is important to consult with a bearing manufacturer or engineer to determine the appropriate fit tolerance based on the specific requirements of the application.

They can provide guidance and help ensure optimal performance and longevity of the bearing system.

Considerations when choosing clearance, interference, or transition fit

When selecting the right bearing fit tolerance,

there are several important considerations to keep in mind when choosing between clearance, interference, or transition fit:

1.The operating conditions of the application can significantly affect the fit tolerance of the bearing.

Consider factors such as temperature, humidity, lubrication, and exposure to chemicals or other corrosive agents.

2.The expected load is another critical factor to consider when selecting the appropriate fit tolerance.

For high loads, an interference fit is typically recommended to provide the necessary stability and support, while for lower loads,

a clearance fit may be suitable to minimize friction and reduce wear.

3.High-speed applications typically require a clearance fit tolerance to minimize friction and reduce heat buildup.

In contrast, an interference fit may be necessary for low-speed or static applications to ensure the bearing stays in place and maintains proper alignment.

4.If the shaft and housing are misaligned, a clearance fit tolerance may be necessary to allow for movement and compensate for any misalignment.

In contrast, an interference fit may be required for applications that require precise alignment.

5.Applications with high levels of impact or shock loads may require a tighter interference fit tolerance to prevent the bearing from shifting or slipping under load.

6.The surface finish of the shaft and housing can affect the fit tolerance of the bearing.

For example, a rough surface finish may require a tighter interference fit tolerance to ensure proper seating and prevent movement.

7.The material of the shaft, housing, and bearing can also affect the fit tolerance.

Different materials may expand or contract at different rates, which can affect the fit.

Calculations and formulas for determining proper fit tolerance

Here are some of the basic formulas and calculations that are used to determine the appropriate fit tolerance:

1.The shaft diameter should be calculated based on the expected load, speed, and other application factors.

2.The housing diameter should be calculated based on the expected load, speed, and other application factors.

3.The fit tolerance can be calculated using the following formulas:

4.The clearance fit tolerance is calculated by subtracting the minimum shaft diameter from the maximum housing diameter.

Clearance fit tolerance = (max. housing diameter - min. shaft diameter)

-The interference fit tolerance is calculated by subtracting the maximum shaft diameter from the minimum housing diameter.

Interference fit tolerance = (min. housing diameter - max. shaft diameter)

-The transition fit tolerance is calculated by taking the average of the clearance and interference fit tolerances.

Transition fit tolerance = (clearance fit tolerance + interference fit tolerance) / 2

-he type of bearing being used will also impact the fit tolerance, as different types of bearings have different tolerances and requirements.

Measuring and Controlling Bearing Fit Tolerance

Methods for measuring fit tolerance

There are several methods for measuring fit tolerance in bearing applications.

Here are some of the most commonly used methods:

1.A micrometer is a precision tool that is commonly used to measure the diameter of shafts, housings, and bearings.

A micrometer is typically used to measure the dimensions of the components and then calculate the fit tolerance.

2.A vernier caliper is another tool that can be used to measure the diameter of shafts, housings, and bearings.

Vernier calipers are available in both analog and digital versions and can provide accurate measurements of the components.

3.Gauge blocks are precision blocks that are used to measure the dimensions of shafts, housings, and bearings.

Gauge blocks can be used to compare the dimensions of the components and calculate the fit tolerance.

4.An optical comparator is a tool that uses a light source and a magnifying lens to compare the dimensions of components.

Optical comparators can provide a highly accurate measurement of the components and the fit tolerance.

5.A CMM (Coordinate Measuring Machine) is a high-precision tool that is used to measure the dimensions of components.

CMMs are commonly used in manufacturing and can provide highly accurate measurements of the components and fit tolerance.

Best practices for achieving precise fit tolerance

Here are some best practices for achieving precise fit tolerance:

1.Accurate measurements of the shaft, housing, and bearing are essential for achieving precise fit tolerance.

Use high-precision measuring tools, such as micrometers or vernier calipers, to ensure accurate measurements.

2.Temperature can have a significant impact on fit tolerance.

Ensure that the components are at the same temperature during installation to avoid any expansion or contraction that could affect the fit.

3.Proper lubrication is essential for ensuring the bearing operates smoothly and can help achieve precise fit tolerance.

Use the recommended lubrication and apply it according to the manufacturer's instructions.

4.Keep the components clean during installation to avoid any dirt or debris that could affect the fit.

5.Proper assembly of the bearing and components is critical for achieving precise fit tolerance.

Follow the manufacturer's instructions and ensure that the bearing is installed in the correct orientation.

6.Use quality control measures to ensure that the components meet the required specifications and tolerances.

7.Test the fit tolerance to ensure that it meets the required specifications and make adjustments if necessary.

Tools and equipment used for controlling fit tolerance

Here are some of the most commonly used tools and equipment for controlling fit tolerance:

1.Surface finish testing equipment is used to measure the surface finish of components.

A smooth surface finish is essential for achieving precise fit tolerance, and surface finish testing equipment can ensure that the components meet the required specifications.

2.Hardness testing equipment is used to measure the hardness of the components.

The hardness of the components can affect the fit tolerance, and hardness testing equipment can ensure that the components meet the required specifications.

3.Quality control equipment, such as digital cameras or microscopes, can be used to inspect the components for any defects or imperfections that could affect the fit tolerance.

Conclusion

Understanding bearing fit tolerance is crucial for achieving optimal performance and longevity of bearings.

Properly selecting, measuring, and controlling fit tolerance can ensure that the components work together seamlessly and provide the desired functionality.