The Advantages of Using Ball Bearings in Machinery: A Guide to Friction Reduction

Looking for a guide to reduce friction in your machinery? Look no further!

This informative guide will take you through the wonderful world of ball bearings.

Dive into the world of ball bearings today and start enjoying the advantages they bring!

Welcome to the wonderful world of ball bearings! Are you tired of dealing with machinery that's sluggish, inefficient, and prone to breakdowns?

Then it's time to discover the many advantages of using ball bearings.

These little wonders can work wonders when it comes to reducing friction, improving efficiency, and extending the lifespan of your equipment.

With this article as your guide, you'll be able to unlock the full potential of your machines and enjoy smoother, more reliable operations than ever before!

Advantages of Using Ball Bearings in Machinery:

Ball bearings can reduce friction in machinery

They improve efficiency and reduce wear and tear on equipment

They can increase the lifespan of machinery

Ball bearings are affordable and widely available

They come in a variety of sizes and materials to suit different applications

Using ball bearings can lead to the smoother, more reliable operation of machinery

With this comprehensive guide as your resource, you'll be able to unlock the full potential of ball bearings, discovering how they can optimize your machinery and streamline your operations.

So don't miss out on all the advantages of using ball bearings - keep reading and start optimizing your equipment today!

What are ball bearings?

Ball bearings are mechanical components that help reduce friction between two surfaces that are in contact with each other.

They are made up of small metal balls that roll between the two surfaces, facilitating smooth movement and minimizing the amount of friction generated.

Ball bearings come in a variety of sizes and materials, and are commonly used in machinery across a wide range of industries to improve efficiency, reliability, and overall performance.

Importance of ball bearings in machinery

Ball bearings play a critical role in the smooth and efficient operation of machinery.

By reducing friction between moving parts, they help to minimize wear and tear on equipment, extend its lifespan, and improve overall performance.

Without ball bearings, machines would be subject to much greater levels of friction, leading to increased heat and energy loss, as well as more frequent breakdowns and repairs.

Additionally, ball bearings come in a wide range of sizes and materials, making them versatile components that can be tailored to suit different types of machinery and applications.

Overall, the importance of ball bearings in machinery cannot be overstated, as they are essential for ensuring optimal performance, reliability, and longevity.

What is friction reduction?

Friction reduction refers to the process of minimizing resistance between two surfaces that are in contact with each other.

Friction is a natural force that opposes the motion of objects and can cause heat generation, energy loss, and wear and tear on materials.

By reducing friction between moving parts, machinery can operate more efficiently and with less stress on its components.

This not only helps to save energy and reduce maintenance costs but also extends the lifespan of the equipment.

One common way to reduce friction is through the use of ball bearings, which work by rolling between the two surfaces, rather than sliding against them.

How Ball Bearings Work

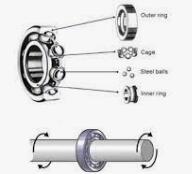

Basic components of ball bearings

Ball bearings are mechanical components that work by reducing friction between two surfaces that are in contact with each other.

They are made up of several basic components, including an outer ring or raceway, an inner ring, rolling elements (typically small metal balls), and a cage or separator that holds the rolling elements in place.

The outer ring and inner ring of a ball bearing are designed to fit around the rotating shaft and stationary housing respectively.

Between these two rings lies a series of balls that roll smoothly along the raceways while transmitting the load from one ring to the other.

The balls act as tiny rollers, minimizing friction and allowing for smooth rotation of the machinery.

Lubrication and its importance in reducing friction

Lubrication is crucial to the function of ball bearings, as it reduces wear and tear on the components and helps to prevent heat buildup.

Lubricants such as oil or grease are applied to the bearing components to reduce friction and ensure that the rolling elements move freely.

Without proper lubrication, friction would increase, leading to more frequent breakdowns and repairs.

Types of ball bearings

Deep groove ball bearings: used in high-speed applications and can handle radial and axial loads.

Angular contact ball bearings: designed to handle both radial and thrust loads and are commonly used in automotive applications.

Thrust ball bearings: designed to handle loads in one direction only and are often used in machines with vertical shafts.

Other types of ball bearings include self-aligning ball bearings, ceramic ball bearings, and miniature ball bearings, among others.

Benefits of Using Ball Bearings in Machinery

Reducing friction and wear

By rolling between moving parts, ball bearings minimize friction and reduce the amount of heat generated during operation.

This helps to prevent wear and tear on components, extending the lifespan of the machinery.

Increasing efficiency and performance

Ball bearings enable smooth movement between parts, allowing machinery to operate more efficiently with less energy loss.

This can lead to increased productivity, reduced maintenance costs, and improved overall performance.

Reducing noise and vibration

The use of ball bearings can help to dampen noise and vibration in machinery, improving working conditions and reducing the risk of damage caused by excessive vibration.

Extending the lifespan of machinery

By reducing wear and tear on components, ball bearings help to extend the lifespan of machinery.

This can save businesses money in the long run, as they won't need to replace equipment as frequently.

Factors Affecting Ball Bearing Performance

Load Capacity

Ball bearings are designed to handle specific loads, and overloading them can cause premature wear and failure.

It's important to choose the right type of bearing for the job and ensure that it can handle the expected load.

Speed

The speed at which a bearing operates can also affect its performance.

If a bearing is used at speeds that exceed its design limits, it may generate excessive heat, leading to premature wear and failure.

Temperature

Ball bearings can be sensitive to changes in temperature, as high temperatures can cause thermal expansion and lead to seizure or failure.

Conversely, low temperatures can cause lubrication to thicken and reduce the effectiveness of the bearing.

Environment

The environment in which a bearing operates can also have an impact on its performance.

Exposure to moisture, dust, and other contaminants can cause corrosion and damage to the bearing components, reducing their lifespan.

Maintenance and Inspection of Ball Bearings

Regular lubrication

Proper lubrication is crucial to reducing friction and wears on ball bearings.

It's important to use the correct lubricant for the application and to apply it at regular intervals as recommended by the manufacturer.

Cleaning and inspection

Ball bearings should be kept clean and inspected regularly for signs of damage or wear.

Any contaminants or debris should be removed with a suitable cleaning agent, and any visible damage to the bearing components should be addressed promptly.

Replacement and repair

If a ball bearing shows signs of significant wear or damage, it may need to be replaced or repaired.

Replacement parts should always be of the same type and quality as the original, and repairs should be carried out by trained professionals using appropriate tools and techniques.

Proper storage

When not in use, ball bearings should be stored in a clean environment free from moisture and dust.

They should be kept in their original packaging or stored in suitable containers to prevent damage.

Applications of Ball Bearings

Automotive

Ball bearings are used extensively in the automotive industry, where they help to reduce friction and improve efficiency.

They can be found in everything from engines and transmissions to wheels and suspension systems.

Aerospace

The aerospace industry relies on ball bearings for a variety of critical applications, such as in jet engines, turbines, and landing gear systems.

Ball bearings must be able to withstand extreme temperatures, pressures, and speeds in these applications.

Industrial

Ball bearings are widely used in industrial machinery, such as conveyors, elevators, and pumps.

They help to reduce friction and improve efficiency, allowing machines to operate more smoothly and reliably.

Medical

Ball bearings are also used in medical equipment, where precision and reliability are essential.

They can be found in everything from surgical instruments and laboratory equipment to MRI machines and X-ray scanners.

Conclusion

In conclusion, the benefits of using ball bearings in machinery are clear.

By minimizing friction and wear, increasing efficiency and performance, reducing noise and vibration, and extending the lifespan of equipment,

ball bearings are a key component for achieving reliable and optimal operation of machinery across a range of industries.

With proper maintenance and inspection, ball bearings can continue to deliver reliable and efficient performance for years to come.