Optimizing Performance with Steel Balls for Bearings

Looking to optimize your bearing performance? Look no further than steel balls!

These little powerhouses pack a punch when it comes to enhancing your equipment's efficiency and durability.

Let's get rolling toward better results!

Welcome to the wonderful world of bearings! Today, we're going to explore how steel balls can help us optimize performance and take our bearings to the next level.

Whether you're a seasoned engineer or just starting out in the field, this is an exciting topic that's sure to bring a smile to your face.

So, sit back, grab a cup of coffee, and let's dive into the fascinating world of bearing optimization with steel balls!

To optimize the performance of steel balls used in bullet-shaped bearings, there are several factors to consider.

Here are some tips that may help:

Material selection:The type of steel used to create the ball is critical to its performance.

High-carbon chrome alloy steel is often used for its durability and ability to withstand high levels of stress.

Surface finish:The surface finish of the steel ball can impact its overall performance.

A smoother surface will reduce friction, leading to less wear and tear on the bearing.

Size accuracy:It's essential to ensure the steel balls' size is accurate to minimize any inconsistencies in the bearing's operation.

Lubrication:Proper lubrication of the bearing can increase its lifespan and improve its overall performance.

Load capacity:It's crucial to determine the maximum load capacity of the bearing to ensure it can handle the expected load without becoming damaged.

In this article, we're going to be talking all about optimizing performance with these little powerhouses!

So why settle for subpar performance when you can unlock the full potential of your machinery with steel balls for bearings?

Let's dive in and explore the exciting world of optimizing performance with these little wonders!

Brief overview of steel balls for bearings

Steel balls for bearings are small, but essential components that play a vital role in the performance of many types of machinery.

These precision-made balls are typically constructed from high-grade steel alloys and are used to reduce friction between moving parts within a bearing assembly.

By reducing friction, they help to improve the efficiency, speed, and durability of bearing systems, leading to better overall performance and longer service life.

Steel balls for bearings come in a variety of sizes, materials, and designs, each with its own unique set of properties and advantages.

Importance of steel balls in the functioning of bearings

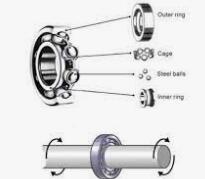

Steel balls play a crucial role in the functioning of bearings. Bearings are used to reduce friction between moving parts and provide support for shafts or other rotating components.

To do this, they need to maintain a specific gap between the stationary outer ring and the rotating inner ring.

Steel balls are used as the rolling elements in most bearings because they are durable, hard, and can withstand high levels of stress and pressure.

When the bearing is in operation, the steel balls roll along the raceways (grooves) on the inner and outer rings, separating them and reducing friction between the two surfaces.

Characteristics of Steel Balls for Bearings

Size

The size of the steel balls used in bearings is critical because it determines the load-bearing capacity of the bearing.

The size of the ball is specified by its diameter, which typically ranges from 0.5mm to 50mm.

Material

The material used to make steel balls for bearings must be strong, durable, and corrosion-resistant.

Most commonly, these balls are made from high-carbon chrome alloy steel.

Other materials, such as stainless steel or ceramic, may also be used depending on the application.

Hardness

The hardness of the steel balls determines their ability to withstand wear and deformation under pressure.

Hardness is measured using the Rockwell scale, and the ideal hardness depends on the type of bearing and its operating conditions.

Surface finish

The surface finish of the steel balls affects how they interact with other surfaces in the bearing assembly.

A smooth surface finish is important to reduce friction and prevent damage to the bearing.

Tolerance

Tolerance refers to the degree of variation permitted in the size and shape of the steel balls.

This is important because even small variations can affect the performance of the bearing.

Tighter tolerances are generally required for precision applications.

Manufacturing Process of Steel Balls for Bearings

Raw Material Selection

The first step in manufacturing steel balls for bearings is selecting the appropriate raw materials.

Typically, the raw materials used are high-quality steel billets that are checked for any defects before being used.

Hot Forging

The next step is hot forging, where the billets are heated to a specific temperature and then shaped into rough balls using dies.

This process helps to improve the internal structure of the steel, making it more durable.

Cold Forging

After hot forging, the balls are cooled down and undergo cold forging.

In this process, the balls are further deformed using dies to achieve their final shape and size.

Heat Treatment

Once the balls are shaped, they undergo heat treatment to improve their hardness and toughness.

The balls are heated to a specific temperature and then quenched in oil or water to harden them. They are then tempered to improve their toughness.

Grinding and Lapping

After heat treatment, the balls undergo grinding and lapping to achieve their final dimensions and surface finish.

This process involves using specialized machines and abrasive materials to remove any imperfections on the surface of the balls.

Final Inspection

The final step in the manufacturing process is inspecting the balls to ensure they meet the required specifications.

This involves performing various tests such as dimensional checks, surface inspections, and hardness tests.

Types of Bearings that use Steel Balls

Deep Groove Ball Bearings

These bearings have deep grooves on both inner and outer rings and are primarily used for radial loads.

They can withstand axial loads in either direction and are suitable for high-speed applications.

Angular Contact Ball Bearings

These bearings have a contact angle between the inner and outer races, which enables them to support both radial and axial loads.

They are typically used in applications where there are high-speed rotations and heavy loads.

Self-Aligning Ball Bearings

These bearings have two rows of steel balls and are designed to self-align when the shaft and housing are misaligned.

They are used in applications where there is shaft deflection or misalignment.

Thrust Ball Bearings

These bearings consist of a single row of steel balls that are designed to carry axial loads in one direction.

They are typically used in applications where there is a need to support heavy axial loads and low-speed rotations.

Applications of Steel Balls for Bearings

Automotive Industry

Steel balls are widely used in the automotive industry to manufacture various components, including wheel bearings, transmission systems, and engines.

In these applications, steel balls ensure smooth and efficient operation of the machinery, while also reducing friction and wear.

Aerospace Industry

The aerospace industry relies heavily on steel balls for its critical applications, such as in navigation systems, engines, and landing gear.

Steel balls provide high load-bearing capacity, corrosion resistance, and long-term reliability even under extreme conditions of pressure and temperature.

Medical Industry

In the medical industry, steel balls are used in a wide range of applications, including orthopedic implants, pacemaker components, and surgical instruments.

The biocompatibility of steel, combined with its strength and durability, makes it an ideal material for these sensitive applications.

Construction Industry

Steel balls are frequently used in the construction industry to support large structures such as bridges, dams, and skyscrapers.

They are also used in cement mixers and other equipment designed to handle heavy loads.

Advantages of Steel Balls for Bearings

High durability and wear resistance

Steel balls are made with durable materials that make them resistant to wear and tear, ensuring they can withstand harsh conditions and last a long time.

High load-bearing capacity

Steel balls have a high load-bearing capacity, meaning they can support heavy loads without breaking or becoming damaged.

This makes them ideal for use in applications where heavy loads need to be supported such as in industrial machinery and equipment.

Low friction and high precision

Steel balls have low friction, which reduces the amount of energy required to keep them moving.

They also offer high precision, ensuring that bearings can operate smoothly and accurately.

Wide range of applications

Steel balls are versatile and can be used in a wide range of applications, including automotive, aerospace, medical, and industrial settings.

Conclusion

In conclusion, optimizing the performance of bearings with steel balls is a crucial aspect in many industrial applications.

It is important to continuously monitor and evaluate the performance of bearings to identify potential issues and implement necessary changes.

By following these best practices, companies can ensure that their equipment operates at maximum capacity, ultimately leading to increased productivity and profitability.